Basic Water Cooling Tower

Categories:Basic Water Cooling Tower Specification: Bench top unit to demonstrate operation of a forced draught cooling tower, comprising tower base with air circulation, water reservoir with heater and make-...

Product

Description

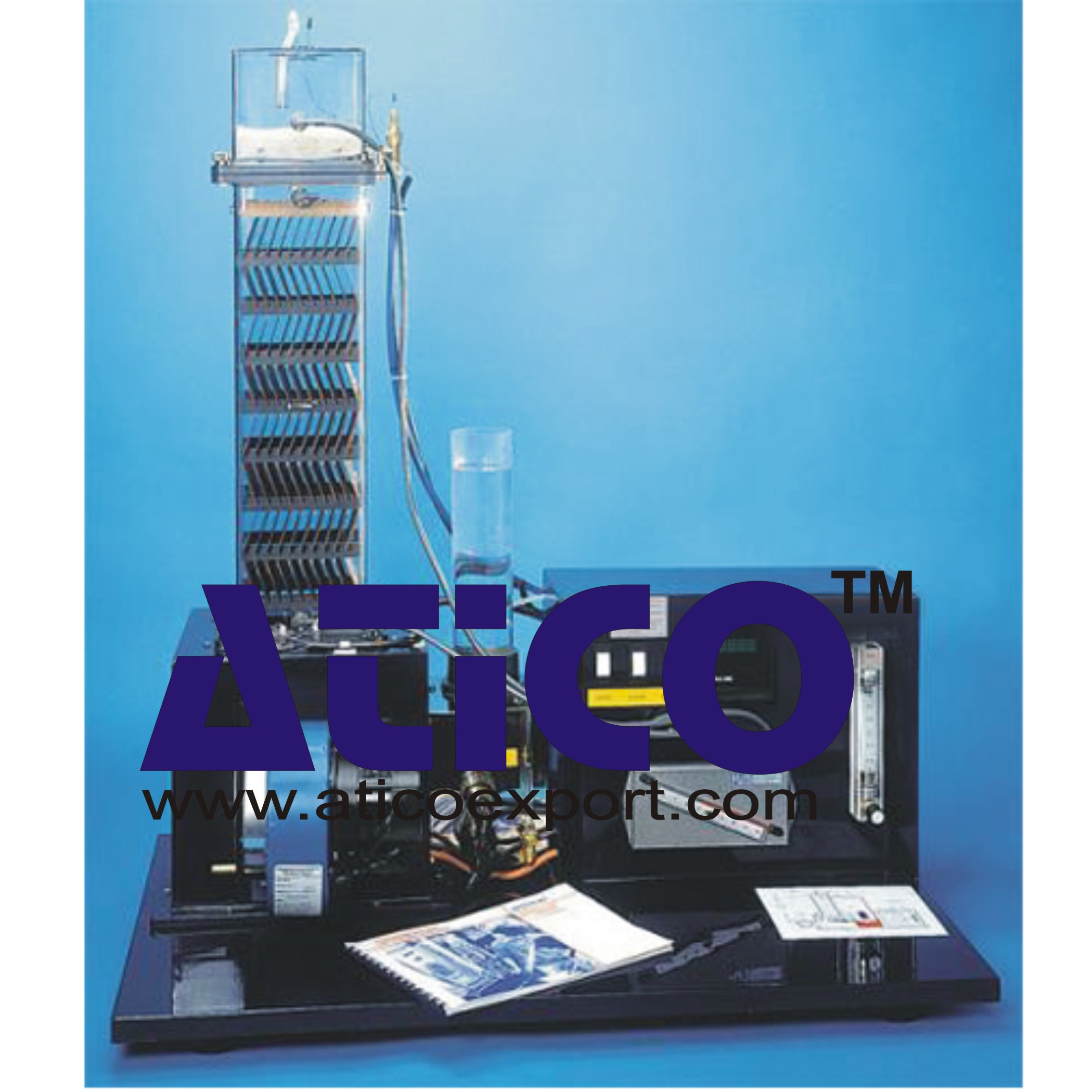

Basic Water Cooling Tower

Specification:

- Bench top unit to demonstrate operation of a forced draught cooling tower, comprising tower base with air circulation, water reservoir with heater and make-up tank, and a control console with recirculation pump and instrumentation

- Supplied with one standard packed column, dimensions 150mm x 150mm x 600mm, comprising 10 plates giving 110m²/m³

- Three additional columns are available as options for comparison (bare column, 7 plates and 18 plates)

- The columns are manufactured from clear plastic to allow viewing of water flow through the system

- The columns are easily interchangeable without the use of tools

Description:

The Basic Water Cooling Tower is completely self-contained and includes both the simulated heating load and the circulating pump. It has much the same configuration as a full size force drought cooling tower, has the same characteristics and stabilizes quickly.

In this unit a fan is placed at the base of the tower to drive air upwards through the packing. Natural buoyancy assists the fan and helps dissipate the humid air from the top of the tower.

The packing in the cooling tower breaks the water into thin films or droplets which present a large surface area to the air stream and thereby assist the cooling process. The water is cooled largely by evaporation and, to a small extent, by direct contact cooling. Due to the evaporation of some of the water into the air stream, a continuous supply of fresh water must be added to the system. This 'make-up' is normally less than 5% of the cooling water flow rate. A float valve is provided to allow accurate measurement of 'make-up'. When the cooled water falls to the load tank it is reheated before circulation.

Technical Details:

Maximum working temperature: 50°C Centrifugal fan, maximum air flow: 0.06kg/s-1 Packed columns: 150mm x 150mm x 600mm high Variable area flow meter: 0 - 50g/s-1 with control valve for water flow rate to packings Temperature measurement using Type K thermocouple displayed on 199.9 digital meter to measure terminal water temperatures and wet and dry bulb air temperatures. Inclined tube manometer: 0 - 40mm H2O to measure orifice differential pressure or packing resistance.

quick overview :

Basic Water Cooling Tower

Specification:

- Bench top unit to demonstrate operation of a forced draught cooling tower, comprising tower base with air circulation, water reservoir with heater and make-up tank, and a control console with recirculation pump and instrumentation

- Supplied with one standard packed column, dimensions 150mm x 150mm x 600mm, comprising 10 plates giving 110m²/m³

- Three additional columns are available as options for comparison (bare column, 7 plates and 18 plates)

- The columns are manufactured from clear plastic to allow viewing of water flow through the system

- The columns are easily interchangeable without the use of tools

Description:

The Basic Water Cooling Tower is completely self-contained and includes both the simulated heating load and the circulating pump. It has much the same configuration as a full size force drought cooling tower, has the same characteristics and stabilizes quickly.

In this unit a fan is placed at the base of the tower to drive air upwards through the packing. Natural buoyancy assists the fan and helps dissipate the humid air from the top of the tower.

The packing in the cooling tower breaks the water into thin films or droplets which present a large surface area to the air stream and thereby assist the cooling process. The water is cooled largely by evaporation and, to a small extent, by direct contact cooling. Due to the evaporation of some of the water into the air stream, a continuous supply of fresh water must be added to the system. This 'make-up' is normally less than 5% of the cooling water flow rate. A float valve is provided to allow accurate measurement of 'make-up'. When the cooled water falls to the load tank it is reheated before circulation.

Technical Details:

Maximum working temperature: 50°C Centrifugal fan, maximum air flow: 0.06kg/s-1 Packed columns: 150mm x 150mm x 600mm high Variable area flow meter: 0 - 50g/s-1 with control valve for water flow rate to packings Temperature measurement using Type K thermocouple displayed on 199.9 digital meter to measure terminal water temperatures and wet and dry bulb air temperatures. Inclined tube manometer: 0 - 40mm H2O to measure orifice differential pressure or packing resistance.

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.