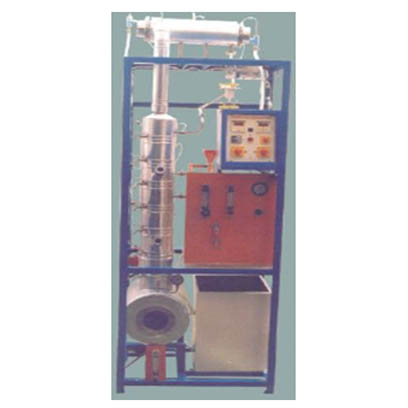

Continuous Distillation Study Unit

Categories: Unit Operation LabDescription: The column is made of Stainless Steel with seven plates for mounting the bubble caps. Each plate is provided with one bubble cap. An electrically heated reboiler is installed at the bott...

Product

Description

Description: The column is made of Stainless Steel with seven plates for mounting the bubble caps. Each plate is provided with one bubble cap. An electrically heated reboiler is installed at the bottom of the column. The bottom product is collected in the tank. The vapours form the top of column are condensed in the shell and tube type condenser by cooling water supplied by laboratory overhead tank. The condensate is divided into reflux and distillate by automatic reflux divider and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation provided for pressure & temp. Measurement wherever necessary. Experimentation: To estimate the batch distillation curves for a binary system and verify the binary batch distillation equation for a known number of theoretical plates. To operate the column under total reflux condition and estimate the minimum number of theoretical Plates required. Utilities Required : Water Supply 2 LPM at 5 m head. Floor Drain. Electricity Supply: 1 Phase, 220 VAC, 6 kW. Required Chemicals. Refractometer for analysis. Technical Details : Distillation Column : Material Stainless Steel, Diameter 110mm seven plates. Feed Pump : Compatible Capacity Feed Tank : Capacity 25 ltrs (approx.) Pressure Gauge : Bourdon type Rotameter : For cooling water flow rate measurement. Steam Generator : Made of Stainless Steel, provided with Pressure Gauge & Level.Indicator, Safety valve & insulated with ceramic wool and cladding with Aluminum foil. Reflux Divider : Special arrangement to change R/D ratio automatically. Condenser : Shell & Tube type made of Stainless Steel. Bottom product tank : Made of Stainless Steel, capacity 5 Liters. Distillate tank : Made of Stainless Steel, capacity 5 Liters. Heater : Nichrome wire heater. Temp. Sensors : RTD PT-100 type Control Panel Comprises of : Digital Temp. Controller : 0-199.9°C, For Re-boiler. Digital Temp. Indicator : 0-199.9°C,with multi-channel switch Standard make On/Off Switch, Mains Indicator, etc. The whole set-up is well designed and arranged on a rigid structure painted with industrial PU Paint. An ENGLISH instruction manual consisting of experimental procedures, block diagram etc. will be provided along with the Apparatus

quick overview :

Description: The column is made of Stainless Steel with seven plates for mounting the bubble caps. Each plate is provided with one bubble cap. An electrically heated reboiler is installed at the bottom of the column. The bottom product is collected in the tank. The vapours form the top of column are condensed in the shell and tube type condenser by cooling water supplied by laboratory overhead tank. The condensate is divided into reflux and distillate by automatic reflux divider and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation provided for pressure & temp. Measurement wherever necessary. Experimentation: To estimate the batch distillation curves for a binary system and verify the binary batch distillation equation for a known number of theoretical plates. To operate the column under total reflux condition and estimate the minimum number of theoretical Plates required. Utilities Required : Water Supply 2 LPM at 5 m head. Floor Drain. Electricity Supply: 1 Phase, 220 VAC, 6 kW. Required Chemicals. Refractometer for analysis. Technical Details : Distillation Column : Material Stainless Steel, Diameter 110mm seven plates. Feed Pump : Compatible Capacity Feed Tank : Capacity 25 ltrs (approx.) Pressure Gauge : Bourdon type Rotameter : For cooling water flow rate measurement. Steam Generator : Made of Stainless Steel, provided with Pressure Gauge & Level.Indicator, Safety valve & insulated with ceramic wool and cladding with Aluminum foil. Reflux Divider : Special arrangement to change R/D ratio automatically. Condenser : Shell & Tube type made of Stainless Steel. Bottom product tank : Made of Stainless Steel, capacity 5 Liters. Distillate tank : Made of Stainless Steel, capacity 5 Liters. Heater : Nichrome wire heater. Temp. Sensors : RTD PT-100 type Control Panel Comprises of : Digital Temp. Controller : 0-199.9°C, For Re-boiler. Digital Temp. Indicator : 0-199.9°C,with multi-channel switch Standard make On/Off Switch, Mains Indicator, etc. The whole set-up is well designed and arranged on a rigid structure painted with industrial PU Paint. An ENGLISH instruction manual consisting of experimental procedures, block diagram etc. will be provided along with the Apparatus

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.