Dynamics Of A Rotating System

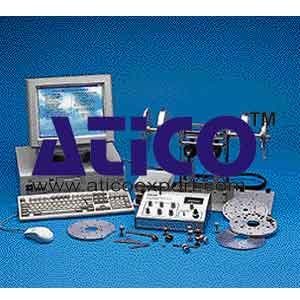

Categories: Mechanical Lab Equipment ManufacturerDynamics Of A Rotating System Dynamics Of A Rotating System: Vibration and out-of-balance forces can be visualised and measured by computer-assisted data acquisition. Static and dynamic balancing is p...

Product

Description

Dynamics Of A Rotating System

Dynamics Of A Rotating System: Vibration and out-of-balance forces can be visualised and measured by computer-assisted data acquisition. Static and dynamic balancing is possible for complex rotating shapes. Specially written simulation software is used to compare the theoretical and the actual performance.Teaching Objectives of Dynamics Of A Rotating System

The range of equipment allows :- Visualisation of vibration and out-of-balance forces.

- Static and dynamic balancing of the assembly without added mass or loaded with one or several masses.

- Dynamic balancing of the assembly loaded with one or several masses and rebalanced using one or more masses, either with or without data acquisition.

- Quantitative study of the various modes of vibration and out-of-balance behaviours.

- Measurement of the forces and displacements on the rotor supports.

- Static and dynamic balance of the rotor unbalanced with complex rotating shapes.

- The simulation software is supplied as standard to illustrate the performance of the rotating system and to select the necessary balance masses.

Technical Specifications of Dynamics Of A Rotating System

The basic unit consists of a shaft rotating through two bearing blocks and equipped with four discs symmetrically on both sides of the supporting blocks. The system is connected elastically to the base plate via two pairs of flat spring steel beams. Small masses of various values can be attached to each disc to balance or unbalance the rotating system. Rotational movement is given to the system manually. The test bench is identical, but two of the flexible steel beams supporting the rotating assembly, are fitted with strain gauges. A magnetic proximity detector fitted adjacent to the rotating shaft permits measurement of instantaneous angular position and speed of rotation. These sensors allow computer-based data acquisition. The apparatus permits all the experimentation but additionally allows the study of the balance of any rotating shape. The two discs closest to the support beams are equipped with rims, allowing the attachment of self-adhesive masses. Furthermore, one of the outer discs can be replaced by a spindle onto which any disc or shape may be attached. Whichever system is used, it is essential that they are fixed securely to a robust support to maximise the accuracy of the test results.Equipment Package:

Basic equipment for the study of rotational systems:- Test bench without instrumentation.

- Set of masses and pull-chord.

- Simulation software.

- Technical manual and teaching notes

- Set of instrumentation (rotational sensor and strain gauges).

- Data acquisition software, interface card, connecting box and cables.

- Technical manual and teaching notes

- Two rims and spindle with standard disc.

- Three complex shapes (disc with missing segment, disc with axial holes, disc of tapered section).

- Technical manual and teaching notes

Dimensions and weight

- 60 x 26 x 45 cm - 14 kg

Essential requirements

- Strain bridge.

- Electrical supply : 220 V – 50 Hz (for the strain bridge).

- PC with CD ROM and free PCI slot - Windows 98, 2000 or XP.

- Solid support for the test bench.

quick overview :

Dynamics Of A Rotating System

Dynamics Of A Rotating System: Vibration and out-of-balance forces can be visualised and measured by computer-assisted data acquisition. Static and dynamic balancing is possible for complex rotating shapes. Specially written simulation software is used to compare the theoretical and the actual performance.Teaching Objectives of Dynamics Of A Rotating System

The range of equipment allows :- Visualisation of vibration and out-of-balance forces.

- Static and dynamic balancing of the assembly without added mass or loaded with one or several masses.

- Dynamic balancing of the assembly loaded with one or several masses and rebalanced using one or more masses, either with or without data acquisition.

- Quantitative study of the various modes of vibration and out-of-balance behaviours.

- Measurement of the forces and displacements on the rotor supports.

- Static and dynamic balance of the rotor unbalanced with complex rotating shapes.

- The simulation software is supplied as standard to illustrate the performance of the rotating system and to select the necessary balance masses.

Technical Specifications of Dynamics Of A Rotating System

The basic unit consists of a shaft rotating through two bearing blocks and equipped with four discs symmetrically on both sides of the supporting blocks. The system is connected elastically to the base plate via two pairs of flat spring steel beams. Small masses of various values can be attached to each disc to balance or unbalance the rotating system. Rotational movement is given to the system manually. The test bench is identical, but two of the flexible steel beams supporting the rotating assembly, are fitted with strain gauges. A magnetic proximity detector fitted adjacent to the rotating shaft permits measurement of instantaneous angular position and speed of rotation. These sensors allow computer-based data acquisition. The apparatus permits all the experimentation but additionally allows the study of the balance of any rotating shape. The two discs closest to the support beams are equipped with rims, allowing the attachment of self-adhesive masses. Furthermore, one of the outer discs can be replaced by a spindle onto which any disc or shape may be attached. Whichever system is used, it is essential that they are fixed securely to a robust support to maximise the accuracy of the test results.Equipment Package:

Basic equipment for the study of rotational systems:- Test bench without instrumentation.

- Set of masses and pull-chord.

- Simulation software.

- Technical manual and teaching notes

- Set of instrumentation (rotational sensor and strain gauges).

- Data acquisition software, interface card, connecting box and cables.

- Technical manual and teaching notes

- Two rims and spindle with standard disc.

- Three complex shapes (disc with missing segment, disc with axial holes, disc of tapered section).

- Technical manual and teaching notes

Dimensions and weight

- 60 x 26 x 45 cm - 14 kg

Essential requirements

- Strain bridge.

- Electrical supply : 220 V – 50 Hz (for the strain bridge).

- PC with CD ROM and free PCI slot - Windows 98, 2000 or XP.

- Solid support for the test bench.

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.