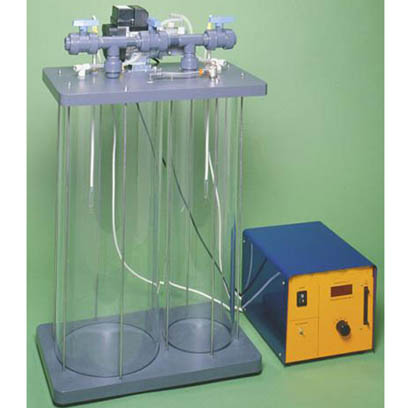

Expansion Processes Of A Perfect Gas Testing For Investigating The Behavior Of Gas

Categories: Thermodynamic LaboratoryDescription The apparatus consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum. An electrically operated air pump connec...

Product

Description

Description The apparatus consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum. An electrically operated air pump connected to the top of the vessels, together with valves and tapings enables the appropriate vessel to be pressurised or evacuated as required to suit the teaching exercise. The vessels can be used independently or together to enable different thermodynamic processes to be evaluated. A pressure sensor connected to each vessel and a temperature sensor inside each vessel permit the changes in the properties of the air contained within the vessels to be monitored continuously.Both vessels are constructed from clear rigid plastic, which affords light insulation between the air inside the vessel and the surroundings to reduce heating/cooling. This also enables each vessel and its contents to return to ambient temperature reasonably quickly. The capacity of the pressurised vessel is approximately 23 liters. The capacity of the evacuated vessel is approximately 11 liters. Specification A small-scale unit designed to introduce students to the properties of a perfect gas using air to demonstrate basic thermodynamic processes The hardware consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum. Appropriate valves and tappings are fitted to enable different thermodynamic processes to be evaluated. An electric air pump is supplied to enable pressurization or evacuation of the vessels as required for the different exercises. Each vessel incorporates a fast response thermistor sensor to monitor the temperature of the air and connection to a piezoelectric pressure sensor All power supplies, signal conditioning circuitry etc., are contained in a simple electrical console with appropriate current protection devices and an RCD for operator protection. Readings from the pressure sensors and thermistors are displayed on a common digital meter with selector switch. A port on the console can be used to connect to a PC using an optional interface device included with the educational software package. Alternatively the signals can be connected to a user-supplied chart recorder A comprehensive instruction booklet describing how to carry out the laboratory teaching exercises is included. Key Features Interconnected vessels operating under pressure and under vacuum are supplied complete with an electric air pump and appropriate instrumentation ready for use This modern version of a classic experiment (attributed to Clément and Désormes) enables pressure and temperature changes to be monitored continuously using a PC (not supplied). Optional teaching software is available for data logging

quick overview :

Description The apparatus consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum. An electrically operated air pump connected to the top of the vessels, together with valves and tapings enables the appropriate vessel to be pressurised or evacuated as required to suit the teaching exercise. The vessels can be used independently or together to enable different thermodynamic processes to be evaluated. A pressure sensor connected to each vessel and a temperature sensor inside each vessel permit the changes in the properties of the air contained within the vessels to be monitored continuously.Both vessels are constructed from clear rigid plastic, which affords light insulation between the air inside the vessel and the surroundings to reduce heating/cooling. This also enables each vessel and its contents to return to ambient temperature reasonably quickly. The capacity of the pressurised vessel is approximately 23 liters. The capacity of the evacuated vessel is approximately 11 liters. Specification A small-scale unit designed to introduce students to the properties of a perfect gas using air to demonstrate basic thermodynamic processes The hardware consists of two floor-standing interconnected rigid vessels, one equipped for operation under pressure and the second under vacuum. Appropriate valves and tappings are fitted to enable different thermodynamic processes to be evaluated. An electric air pump is supplied to enable pressurization or evacuation of the vessels as required for the different exercises. Each vessel incorporates a fast response thermistor sensor to monitor the temperature of the air and connection to a piezoelectric pressure sensor All power supplies, signal conditioning circuitry etc., are contained in a simple electrical console with appropriate current protection devices and an RCD for operator protection. Readings from the pressure sensors and thermistors are displayed on a common digital meter with selector switch. A port on the console can be used to connect to a PC using an optional interface device included with the educational software package. Alternatively the signals can be connected to a user-supplied chart recorder A comprehensive instruction booklet describing how to carry out the laboratory teaching exercises is included. Key Features Interconnected vessels operating under pressure and under vacuum are supplied complete with an electric air pump and appropriate instrumentation ready for use This modern version of a classic experiment (attributed to Clément and Désormes) enables pressure and temperature changes to be monitored continuously using a PC (not supplied). Optional teaching software is available for data logging

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.