Fluidisation and Fluid Bed Heat Transfer Unit

Categories: Applied Mechanics Lab Equipments[subtitle2] Fluidisation and Fluid Bed Heat Transfer Unit[/subtitle2] Application of fluidised beds is more widespread in industry than is usually appreciated, covering such diverse fields as po...

Product

Description

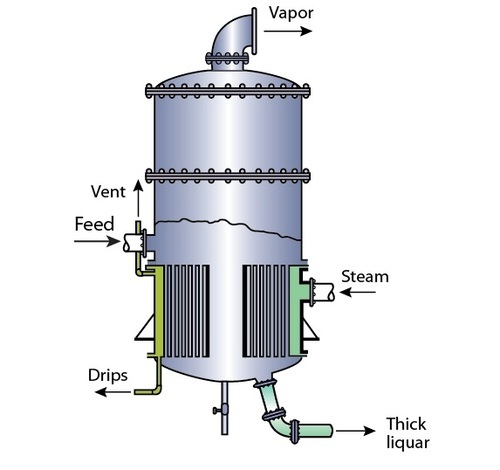

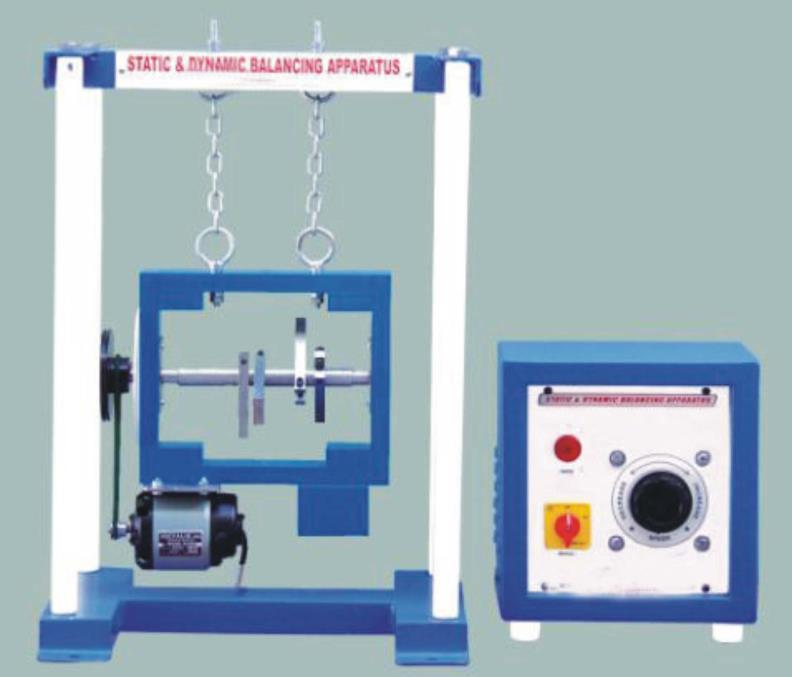

[subtitle2] Fluidisation and Fluid Bed Heat Transfer Unit[/subtitle2] Application of fluidised beds is more widespread in industry than is usually appreciated, covering such diverse fields as power generation to food processing. The objective of the unit is to investigate the gas flow through a fixed and fluidised bed and to measure the heat transfer rate and coefficients for comparison with convective heat transfer rates in air. Fluidisation takes place within a transparent chamber and the range of bed material supplied can be rapidly changed. Alternative locally sourced bed materials and air distributors can be easily utilised for student project work. Specification:

- Fluidised Bed designed for educational studies and using air as the fluidising medium. The unit incorporates a glass chamber containing the bed material and an electric heater for heat transfer studies.

- High quality glass reinforced plastic on which the following components are mounted:

- Variable Transformer to vary the heater power input.

- Volt and Ammeter to indicate the heater power input. Ranges 0 to 250 V amd 0 to 3 A.

- Flow Meters to measure air flow through bed. Range 0.15 to 3.5 litres/sec.

- Digital Thermometer to indicate the temperatures of heater surface, air inlet and probe. Resloution 10C.

- Manometer to measure pressure drop through bed.

- Safety Features include fusing and earthing of all components and heater temperature controller.

- 250 W Single Phase, 220-240 Volts, 50Hz (With earth/ground)

- 250 W Single Phase, 110-120 Volts, 60Hz (With earth/ground).

- 200 litres free air per minute at a pressure of 200 to 1000 kN m-2 gauge.

quick overview :

[subtitle2] Fluidisation and Fluid Bed Heat Transfer Unit[/subtitle2] Application of fluidised beds is more widespread in industry than is usually appreciated, covering such diverse fields as power generation to food processing. The objective of the unit is to investigate the gas flow through a fixed and fluidised bed and to measure the heat transfer rate and coefficients for comparison with convective heat transfer rates in air. Fluidisation takes place within a transparent chamber and the range of bed material supplied can be rapidly changed. Alternative locally sourced bed materials and air distributors can be easily utilised for student project work. Specification:

- Fluidised Bed designed for educational studies and using air as the fluidising medium. The unit incorporates a glass chamber containing the bed material and an electric heater for heat transfer studies.

- High quality glass reinforced plastic on which the following components are mounted:

- Variable Transformer to vary the heater power input.

- Volt and Ammeter to indicate the heater power input. Ranges 0 to 250 V amd 0 to 3 A.

- Flow Meters to measure air flow through bed. Range 0.15 to 3.5 litres/sec.

- Digital Thermometer to indicate the temperatures of heater surface, air inlet and probe. Resloution 10C.

- Manometer to measure pressure drop through bed.

- Safety Features include fusing and earthing of all components and heater temperature controller.

- 250 W Single Phase, 220-240 Volts, 50Hz (With earth/ground)

- 250 W Single Phase, 110-120 Volts, 60Hz (With earth/ground).

- 200 litres free air per minute at a pressure of 200 to 1000 kN m-2 gauge.

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.