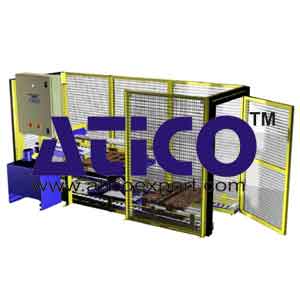

Industrial Palletizer Tri Tech

Categories: Lab EquipmentIndustrial Palletizer Tri Tech Industrial Palletizer Tri Tech Mechanically welded fame with protective grille enclosure including: A table with rollers for the supply of the palletizer. A pallet...

Product

Description

Industrial Palletizer Tri Tech

Industrial Palletizer Tri TechMechanically welded fame with protective grille enclosure including:

- A table with rollers for the supply of the palletizer.

- A palletization table actuated by an hydraulic lifting jack of diameter 50 mm and secured by a balancing valve.

- A loading device actuated by a translation hydraulic jack.

- A table with rollers for the emptying of the pallets.

- Access to the machine by a door with a door electric contact and a key locking device.

- A motor-pump device 0,75 kW, 3 liters/minute, pressure: 80 bars.

- A tank of 28 liters equipped with a visual level, with thermometer,an air filter, a filling and draining plugs, and a backflow filter.

- A pressure limiter.

- A pressure gauge.

- Three electro-hydraulics distributors.

- Two flow limiters.

- A set of hydraulic cables.

- A set of protective hydraulic plugs.

A control cabinet equipped of:

- A PLC Schneider NANO including 9 inputs and 7 outputs, a UNITEL WAY port and a RS485 MOD-BUS port.

- An interactive terminal MAGELIS XBTP, 2 lines of 16 characters and 12 keys functionsA magneto thermal starting and protection system for the motor starting.

- A safety logic block (PREVENTA or equivalent) to manage the openings of the doors.

- A power on light.

- An emergency stop button.

- A padlocked disconnecting switch.

- A power on button.

- Predisposition for the electric actuator.

- Predisposition for the pneumatics pre-actuators and the electric actuator.

- Opto-Electronic.

- Inductive of proximity.

- Safety detection with key for the doors.

Technologies of the actuators: Industrial Palletizer Tri Tech

Hydraulic technology:- The equipment is equipped of origin with hydraulic actuators on the loading device and on the palletization table. These actuators can be replaced, respectively, by a pneumatic and an electric equivalent.

- The package is provided with a replacement kit of the palletization hydraulic jack (jack of the table) by an electric jack. It is supplied with all the connecting accessories.

- The package is supplied with a replacement kit of the table loading hydraulic jack by an pneumatic jack equipped with a flow limiter. It is supplied with all the connecting accessories, an FRL plate with a safety solenoid valve, a pneumatic distributor.

- 15 steel plates: thickness 4 - 400 x 400 mm.

- 15 panels of "Medium": thickness 20 - 400 x 400 mm.

- The technical manual.

- The training manual, dedicated to Maintenance.

- " Breakdowns" Kit, including some real, deficient components.

- 1 deficient hydraulic jack.

- 1 distributor coil in short circuit.

- 1 deficient distributor (worn-out slide).

- 1 deficient limit switch.

- 1 deficient inductive sensor.

- 1 deficient safety lock.

Options:

- Subsystems for technological studies.

- Complementary lift table.

- Complementary hydraulic power station.

- Complementary hydraulic Jack.

Supervision:

- The software communicates in MOD BUS by a RS485 link with the PLC. It allows mainly the access to the parameterization by various application windows and a data historization of the alarms.

Dimensions and weight

- (L x l x w): 4600 x 1600 x 1700 mm - 450 kg.

quick overview :

Industrial Palletizer Tri Tech

Industrial Palletizer Tri TechMechanically welded fame with protective grille enclosure including:

- A table with rollers for the supply of the palletizer.

- A palletization table actuated by an hydraulic lifting jack of diameter 50 mm and secured by a balancing valve.

- A loading device actuated by a translation hydraulic jack.

- A table with rollers for the emptying of the pallets.

- Access to the machine by a door with a door electric contact and a key locking device.

- A motor-pump device 0,75 kW, 3 liters/minute, pressure: 80 bars.

- A tank of 28 liters equipped with a visual level, with thermometer,an air filter, a filling and draining plugs, and a backflow filter.

- A pressure limiter.

- A pressure gauge.

- Three electro-hydraulics distributors.

- Two flow limiters.

- A set of hydraulic cables.

- A set of protective hydraulic plugs.

A control cabinet equipped of:

- A PLC Schneider NANO including 9 inputs and 7 outputs, a UNITEL WAY port and a RS485 MOD-BUS port.

- An interactive terminal MAGELIS XBTP, 2 lines of 16 characters and 12 keys functionsA magneto thermal starting and protection system for the motor starting.

- A safety logic block (PREVENTA or equivalent) to manage the openings of the doors.

- A power on light.

- An emergency stop button.

- A padlocked disconnecting switch.

- A power on button.

- Predisposition for the electric actuator.

- Predisposition for the pneumatics pre-actuators and the electric actuator.

- Opto-Electronic.

- Inductive of proximity.

- Safety detection with key for the doors.

Technologies of the actuators: Industrial Palletizer Tri Tech

Hydraulic technology:- The equipment is equipped of origin with hydraulic actuators on the loading device and on the palletization table. These actuators can be replaced, respectively, by a pneumatic and an electric equivalent.

- The package is provided with a replacement kit of the palletization hydraulic jack (jack of the table) by an electric jack. It is supplied with all the connecting accessories.

- The package is supplied with a replacement kit of the table loading hydraulic jack by an pneumatic jack equipped with a flow limiter. It is supplied with all the connecting accessories, an FRL plate with a safety solenoid valve, a pneumatic distributor.

- 15 steel plates: thickness 4 - 400 x 400 mm.

- 15 panels of "Medium": thickness 20 - 400 x 400 mm.

- The technical manual.

- The training manual, dedicated to Maintenance.

- " Breakdowns" Kit, including some real, deficient components.

- 1 deficient hydraulic jack.

- 1 distributor coil in short circuit.

- 1 deficient distributor (worn-out slide).

- 1 deficient limit switch.

- 1 deficient inductive sensor.

- 1 deficient safety lock.

Options:

- Subsystems for technological studies.

- Complementary lift table.

- Complementary hydraulic power station.

- Complementary hydraulic Jack.

Supervision:

- The software communicates in MOD BUS by a RS485 link with the PLC. It allows mainly the access to the parameterization by various application windows and a data historization of the alarms.

Dimensions and weight

- (L x l x w): 4600 x 1600 x 1700 mm - 450 kg.

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.