Ion Exchange Pilot

Categories: Lab EquipmentIon Exchange Pilot Teaching objectives According to the analysis of the water and flow to be treated or the desired quality to obtain, one can choose. The resin to test. The type of regenerating....

Product

Description

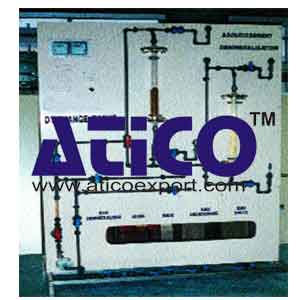

Ion Exchange Pilot

Teaching objectives

- According to the analysis of the water and flow to be treated or the desired quality to obtain, one can choose.

- The resin to test.

- The type of regenerating.

- The quantity of regenerating.

- The flow and function type (co-current, counter-current).

- Measuring the resin capacity according to the regeneration and then calculation the material balances (Ca²+, TH, TA, TAC).

Technical specifications

- Two Altuglass columns (for regeneration)..

- Two Altuglass columns (for processing).

- The columns are removable to change the resins.

- 1 litre of anionic resin.

- 1 litre of cationic resin.

- 1 polypropylene centrifugal pump.

- 5 transparent PVC tanks.

- 1 Conductivity measuring sensor with digital display.

- Five measuring sensor layouts. The measuring sensors are moved in the layouts according to the chosen processes.

- Two fluid circuits to feeding the columns either in co-current or counter-current mode.

- Control panel including a synoptic with diodes to improve the circuit understanding according to the different regeneration /processing stages. It includes the pump control and safety protection, the conductivity measuring transmitters. All the piping is in PVC, the pilot is mounted on a stainless steel frame.

Option :

- Another conductivity measuring sensor with digital display

Dimensions

- 1400 x 800 x 1900 mm

Essential requirements

- Power supply : 220V / single phase / 50 Hz - Power consumption : 80 W.

- Strong cationic resin : Purolite C100 - Strong anionic resin : Purolite A200 HCI 5%, NaOH 5%.

quick overview :

Ion Exchange Pilot

Teaching objectives

- According to the analysis of the water and flow to be treated or the desired quality to obtain, one can choose.

- The resin to test.

- The type of regenerating.

- The quantity of regenerating.

- The flow and function type (co-current, counter-current).

- Measuring the resin capacity according to the regeneration and then calculation the material balances (Ca²+, TH, TA, TAC).

Technical specifications

- Two Altuglass columns (for regeneration)..

- Two Altuglass columns (for processing).

- The columns are removable to change the resins.

- 1 litre of anionic resin.

- 1 litre of cationic resin.

- 1 polypropylene centrifugal pump.

- 5 transparent PVC tanks.

- 1 Conductivity measuring sensor with digital display.

- Five measuring sensor layouts. The measuring sensors are moved in the layouts according to the chosen processes.

- Two fluid circuits to feeding the columns either in co-current or counter-current mode.

- Control panel including a synoptic with diodes to improve the circuit understanding according to the different regeneration /processing stages. It includes the pump control and safety protection, the conductivity measuring transmitters. All the piping is in PVC, the pilot is mounted on a stainless steel frame.

Option :

- Another conductivity measuring sensor with digital display

Dimensions

- 1400 x 800 x 1900 mm

Essential requirements

- Power supply : 220V / single phase / 50 Hz - Power consumption : 80 W.

- Strong cationic resin : Purolite C100 - Strong anionic resin : Purolite A200 HCI 5%, NaOH 5%.

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.