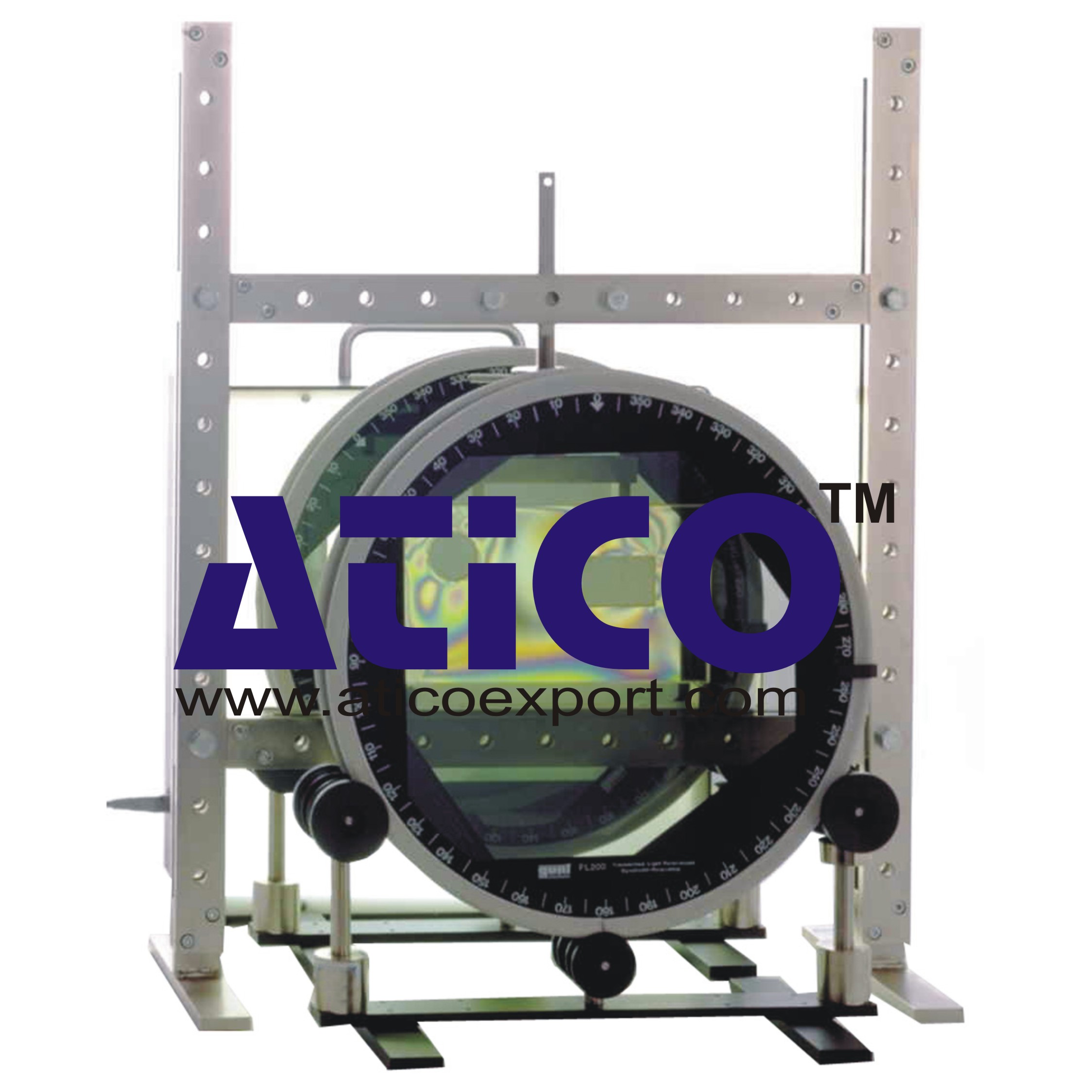

Photoelastic Experiments with Transmission Polariscope

Categories:Photoelasticity is a tried and proven method of analysing and recording mechanical stresses and strains in components. It is deployed for quantitative measurement and to demonstrate complex stress sta...

Product

Description

Photoelasticity is a tried and proven method of analysing and recording mechanical stresses and strains in components. It is deployed for quantitative measurement and to demonstrate complex stress states. The components used are models made of transparent, photoelastically sensitive plastic which becomes optically double-refractive under mechanical loading. This is used to perform photoelastic experiments on flat, transparent plastic models. The models are subjected to loading by external forces, and have circular polarised light shone through them. An analyser analyses the light which has penetrated the body. The experimental setup comprises the following components: A light source, four filters (to generate circular polarised light) and a frame inside which the models are attached and subjected to loading. The light source optionally permits coloured stress patterns with white light or light / dark representation with monochromatic light. The combination of a polarisation filter and a quarter wave plate generates circular polarised light. Behind the model is a second quarter wave plate (perpendicular to the first one), combined with a second polarisation filter. The filters are mounted on rotating bearings and provided with angle scales. Various models are mounted inside the frame. A load application device applies bending, tensile or compressive load to the model by way of a spindle. Stresses and strains occurring in the model are identifiable as bright spots, visualising the distribution of stress. To determine the principal stress difference, the order of the dark isochromatics is evaluated.

Specification:

- Representation of mechanical distribution of stress in photoelastic experiments

- plane polarisation filters as polariser and analyser

- quarter wave filters to generate circular polarised light

- All filters with 360° angle scale and marking of the main optical axis

- White light generated using a fluorescent tube and two incandescent lamps

- Monochromatic light (colour yellow) generated using a sodium vapour lamp

- Filters roller bearing mounted and rotating

- Frame cross-arms height-adjustable

- Generation of compression or tension forces by means of a threaded spindle

- Complete models in polycarbonate (PC) for demonstration purposes available as accessories

Technical Data:

Light source- lamp box with white diffuser - for white light 1 fluorescent tube 2 incandescent lamps, candle bulb, matt inner E14, 235V, 25W

- for monochromatic light (colour yellow) 1 sodium vapour lamp SOX 35, 35W Filter, enclosed in glass, diameter: d=425mm - 2 polarisation filters (dark olive) - 2 quarter wave filters (colourless)

Frame WxH: 600x750mm

quick overview :

Photoelasticity is a tried and proven method of analysing and recording mechanical stresses and strains in components. It is deployed for quantitative measurement and to demonstrate complex stress states. The components used are models made of transparent, photoelastically sensitive plastic which becomes optically double-refractive under mechanical loading. This is used to perform photoelastic experiments on flat, transparent plastic models. The models are subjected to loading by external forces, and have circular polarised light shone through them. An analyser analyses the light which has penetrated the body. The experimental setup comprises the following components: A light source, four filters (to generate circular polarised light) and a frame inside which the models are attached and subjected to loading. The light source optionally permits coloured stress patterns with white light or light / dark representation with monochromatic light. The combination of a polarisation filter and a quarter wave plate generates circular polarised light. Behind the model is a second quarter wave plate (perpendicular to the first one), combined with a second polarisation filter. The filters are mounted on rotating bearings and provided with angle scales. Various models are mounted inside the frame. A load application device applies bending, tensile or compressive load to the model by way of a spindle. Stresses and strains occurring in the model are identifiable as bright spots, visualising the distribution of stress. To determine the principal stress difference, the order of the dark isochromatics is evaluated.

Specification:

- Representation of mechanical distribution of stress in photoelastic experiments

- plane polarisation filters as polariser and analyser

- quarter wave filters to generate circular polarised light

- All filters with 360° angle scale and marking of the main optical axis

- White light generated using a fluorescent tube and two incandescent lamps

- Monochromatic light (colour yellow) generated using a sodium vapour lamp

- Filters roller bearing mounted and rotating

- Frame cross-arms height-adjustable

- Generation of compression or tension forces by means of a threaded spindle

- Complete models in polycarbonate (PC) for demonstration purposes available as accessories

Technical Data:

Light source- lamp box with white diffuser - for white light 1 fluorescent tube 2 incandescent lamps, candle bulb, matt inner E14, 235V, 25W

- for monochromatic light (colour yellow) 1 sodium vapour lamp SOX 35, 35W Filter, enclosed in glass, diameter: d=425mm - 2 polarisation filters (dark olive) - 2 quarter wave filters (colourless)

Frame WxH: 600x750mm

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.