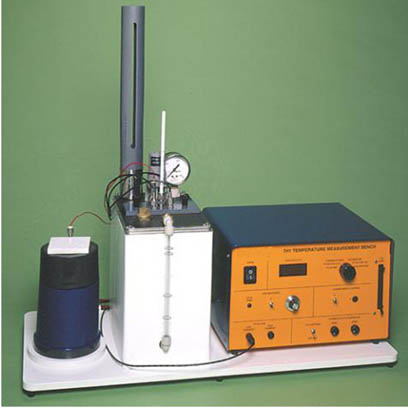

Plunger Pump Demonstration Unit

Categories: Thermodynamic LaboratoryA small-scale plunger pump demonstration unit, comprising of a water reservoir, pump, control valve, relief valve and interconnecting pipe work, all mounted on a stainless steel base. Includes bot...

Product

Description

- A small-scale plunger pump demonstration unit, comprising of a water reservoir, pump, control valve, relief valve and interconnecting pipe work, all mounted on a stainless steel base.

- Includes both a sprung loading valve and a needle valve for loading the pump.

- Equipped with electronic measurement sensors for cylinder pressure, plunger position, pump outlet pressure and cumulative flow.

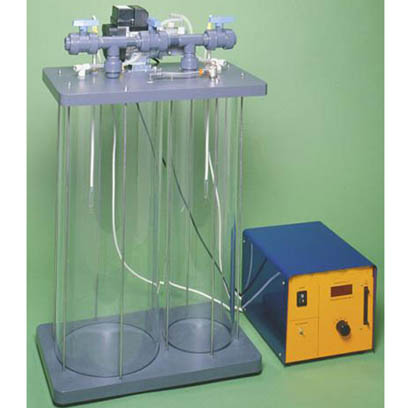

- Pulsation damping facility.

- Transparent pump head for visibility.

- Capable of being linked to a PC (not supplied) via an interface console (an essential accessory).

- Supplied with software providing full instructions for setting up, operating, calibrating and performing the teaching exercises. Facilities provided for logging, processing and displaying data graphically.

- Full theoretical back-up included together with a student questions and answers session.

Capabilities:

- Measurement during each pump cycle of:

- plunger displacement

- cylinder pressure pump outlet pressure

- pump outlet pressure

- On-line P-V diagram displays

- Measurement of volumetric efficiency

- Measuring the effect on pump performance of:

- sprung loading valve or needle valve adjusting the outlet loading valve

- adjusting the outlet loading valve the inclusion of a pulsation damper vessel

- the inclusion of a pulsation damper vessel

Technical Specification:

- Max flow rate: 0.725 l/m typical

- Max head: 4 bar

- Swept volume: 15mm stroke x 32mm diameter

- Pumping speed: variable up to 60 strokes/minute

- Motor power rating: 250W

quick overview :

- A small-scale plunger pump demonstration unit, comprising of a water reservoir, pump, control valve, relief valve and interconnecting pipe work, all mounted on a stainless steel base.

- Includes both a sprung loading valve and a needle valve for loading the pump.

- Equipped with electronic measurement sensors for cylinder pressure, plunger position, pump outlet pressure and cumulative flow.

- Pulsation damping facility.

- Transparent pump head for visibility.

- Capable of being linked to a PC (not supplied) via an interface console (an essential accessory).

- Supplied with software providing full instructions for setting up, operating, calibrating and performing the teaching exercises. Facilities provided for logging, processing and displaying data graphically.

- Full theoretical back-up included together with a student questions and answers session.

Capabilities:

- Measurement during each pump cycle of:

- plunger displacement

- cylinder pressure pump outlet pressure

- pump outlet pressure

- On-line P-V diagram displays

- Measurement of volumetric efficiency

- Measuring the effect on pump performance of:

- sprung loading valve or needle valve adjusting the outlet loading valve

- adjusting the outlet loading valve the inclusion of a pulsation damper vessel

- the inclusion of a pulsation damper vessel

Technical Specification:

- Max flow rate: 0.725 l/m typical

- Max head: 4 bar

- Swept volume: 15mm stroke x 32mm diameter

- Pumping speed: variable up to 60 strokes/minute

- Motor power rating: 250W

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.