Recycling Loops (With Educational Software)

Categories: Thermodynamic LaboratoryDescription A bench top unit designed to introduce students to the characteristics of a recycle loop and the typical responses under steady state and unsteady state conditions. The apparatus consist...

Product

Description

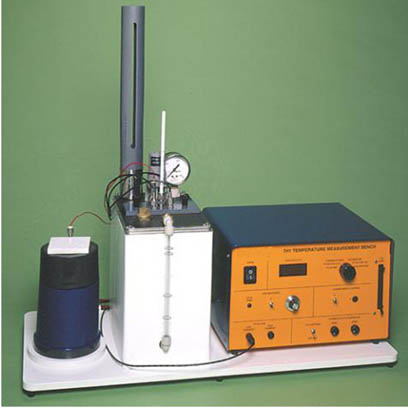

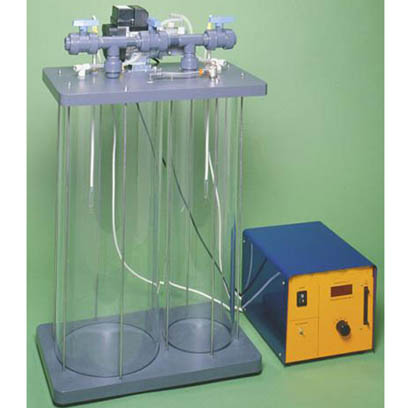

Description A bench top unit designed to introduce students to the characteristics of a recycle loop and the typical responses under steady state and unsteady state conditions. The apparatus consists of a through pipe conveying water from a cold water supply to a suitable drain with a loop of pipework connected between the supply and drain connections. This recycle loop incorporates a circulating pump and a heater to raise the temperature of the water in the loop. The heater can be switched on or off to generate step changes when investigating the transient responses of the recycle loop. A pair of self-sealing fittings enables a short length of pipe or a reservoir to be connected in series with the recyle loop to change the volume of the loop and demonstrate the effect of residence time. The arrangement also permits different lengths of flexible tubing to be connected in series with the loop if it is required to create further changes in residence time. Water temperatures at the inlet, outlet and within the recycle loop are measured using K-type thermocouples. Water flow rates at the corresponding locations are measured using miniature turbine type flow sensors. Flow sensors are included at the outlet as well as the inlet to show that these two flow rates are always equal (a simple principle that is often confusing when water is flowing through the recycle loop). All power supplies, signal conditioning circuitry etc are contained inside the moulded ABS support and integral console with appropriate current protection devices and an RCD for operator protection. Readings from the sensors are displayed on a digital meter with selector switch and all corresponding signals are routed to an I/O port for connection to a PC using an optional interface device included with educational software package. Specification A bench top unit comprising a vacuum formed ABS plastic plinth with integral electrical console on to which is mounted a through pipe with a recycle loop, which incorporates a circulating pump and heater A pressure regulator with filter at the inlet to the apparatus minimises the effect of fluctuations in the cold water supply pressure. Water in the recycle loop is heated by a 2kW electric heater with overtemperature protection. Flow in the loop can be varied from 0 (no recycle) to 3 l/min. The through flow of water can be varied from 0-1.5 l/min Temperatures at the entry to the system, at the exit from the system and inside the recycle loop are measured using K-type thermocouples. Flow rates at corresponding locations are measured using turbine type flow sensors. A reservoir with self-sealing fittings enables the volume of the loop to be changed All electrical circuits are protected by appropriate protection devices The console incorporates a digital meter with selector switch, which displays the temperatures and flow rates measured. Corresponding signals are routed to an I/O port for connection to a PC An optional interface device and educational software package is available A comprehensive instruction manual is included with a range of fully detailed laboratory teaching exercises. Key Features The small-scale of the loop ensures that responses can be fully evaluated in a normal laboratory session Water is used as the working fluid for safety and ease of use

quick overview :

Description A bench top unit designed to introduce students to the characteristics of a recycle loop and the typical responses under steady state and unsteady state conditions. The apparatus consists of a through pipe conveying water from a cold water supply to a suitable drain with a loop of pipework connected between the supply and drain connections. This recycle loop incorporates a circulating pump and a heater to raise the temperature of the water in the loop. The heater can be switched on or off to generate step changes when investigating the transient responses of the recycle loop. A pair of self-sealing fittings enables a short length of pipe or a reservoir to be connected in series with the recyle loop to change the volume of the loop and demonstrate the effect of residence time. The arrangement also permits different lengths of flexible tubing to be connected in series with the loop if it is required to create further changes in residence time. Water temperatures at the inlet, outlet and within the recycle loop are measured using K-type thermocouples. Water flow rates at the corresponding locations are measured using miniature turbine type flow sensors. Flow sensors are included at the outlet as well as the inlet to show that these two flow rates are always equal (a simple principle that is often confusing when water is flowing through the recycle loop). All power supplies, signal conditioning circuitry etc are contained inside the moulded ABS support and integral console with appropriate current protection devices and an RCD for operator protection. Readings from the sensors are displayed on a digital meter with selector switch and all corresponding signals are routed to an I/O port for connection to a PC using an optional interface device included with educational software package. Specification A bench top unit comprising a vacuum formed ABS plastic plinth with integral electrical console on to which is mounted a through pipe with a recycle loop, which incorporates a circulating pump and heater A pressure regulator with filter at the inlet to the apparatus minimises the effect of fluctuations in the cold water supply pressure. Water in the recycle loop is heated by a 2kW electric heater with overtemperature protection. Flow in the loop can be varied from 0 (no recycle) to 3 l/min. The through flow of water can be varied from 0-1.5 l/min Temperatures at the entry to the system, at the exit from the system and inside the recycle loop are measured using K-type thermocouples. Flow rates at corresponding locations are measured using turbine type flow sensors. A reservoir with self-sealing fittings enables the volume of the loop to be changed All electrical circuits are protected by appropriate protection devices The console incorporates a digital meter with selector switch, which displays the temperatures and flow rates measured. Corresponding signals are routed to an I/O port for connection to a PC An optional interface device and educational software package is available A comprehensive instruction manual is included with a range of fully detailed laboratory teaching exercises. Key Features The small-scale of the loop ensures that responses can be fully evaluated in a normal laboratory session Water is used as the working fluid for safety and ease of use

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.