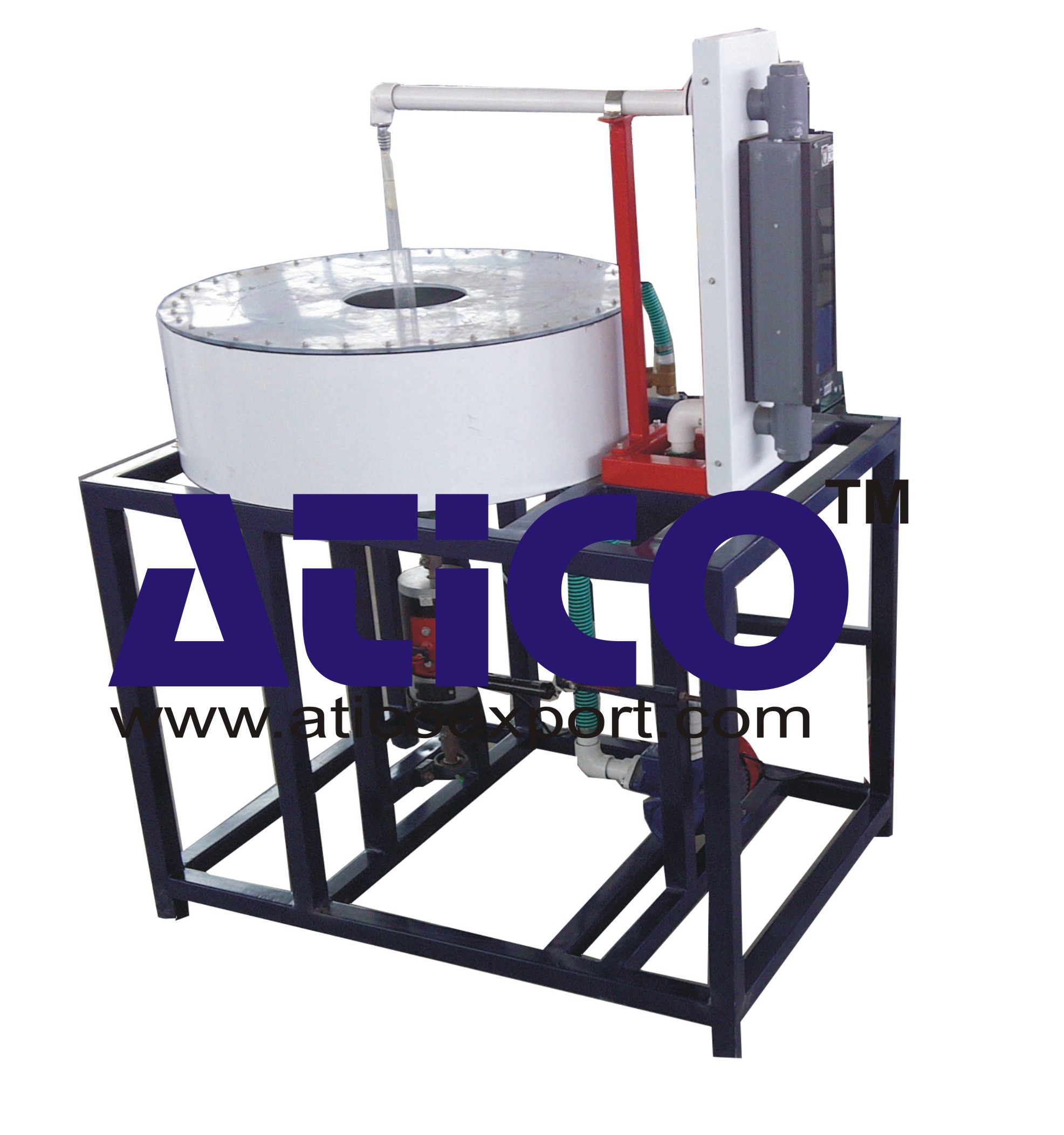

Rod Mill

Categories:Rod Mills are horizontal rotating cylindrical steel chamber of half filled with steel rods of length slightly less than the length of chamber. The rods are of different diameter. The size reduction is...

Product

Description

Rod Mills are horizontal rotating cylindrical steel chamber of half filled with steel rods of length slightly less than the length of chamber. The rods are of different diameter. The size reduction is accomplished by the impact of rods as they fall back after being lifted by the rotating chamber. Rod Mill is fitted on a sturdy MS frame. Charging of rods and material is done by the means of opening provided in the chamber. The chamber is turning about the horizontal axis through a reduction gearbox drive through a ½ HP motor. The stepped pulley arrangement is done for moving the Rod Mill at three different speeds. A revolution counter is provided to find out the number of turns. Special arrangement is done to free the Rod Mill from reduction gearbox for charging and discharging the material.

Experimentation:

- To study effect of RPM on the power consumption of a Rod Mill.

- To determine the efficiency of a Rod Mill for grinding a material of known

Utilities Required :

- Raw Material for Feed.

- Electric Supply : Single phase, 220 V AC, 1 kW.

- Set of Sieves with Sieve Shaker for analysis.

- Floor area 1.5 x 1m

Technical Details :

| Rod Mill | : Material MS |

| : Dia 275mm, Length 350mm. Thickness 5 mm | |

| Discharge Chute | : Suitable size. |

| Drive | : ½ HP motor coupled to Reduction Gearbox & 3 step pulley to get 40, 50 and 60 RPM (Approx.) |

| Revolution Counter | : Mechanical type. |

| Product receiver | : Material Stainless Steel of suitable size. |

| Control Panel Comprises of: | |

| Energy Measurement | : Electronic Energy meter. |

| MCB | : For overload protection. |

| : Standard make on/off switch, Mains Indicator etc. | |

| Instruction Manual | : An ENGLISH instruction manual will be provided along with the Apparatus |

| The set-up is fitted with required guards. | |

| The whole set-up is well designed and arranged in a good quality painted structure. | |

quick overview :

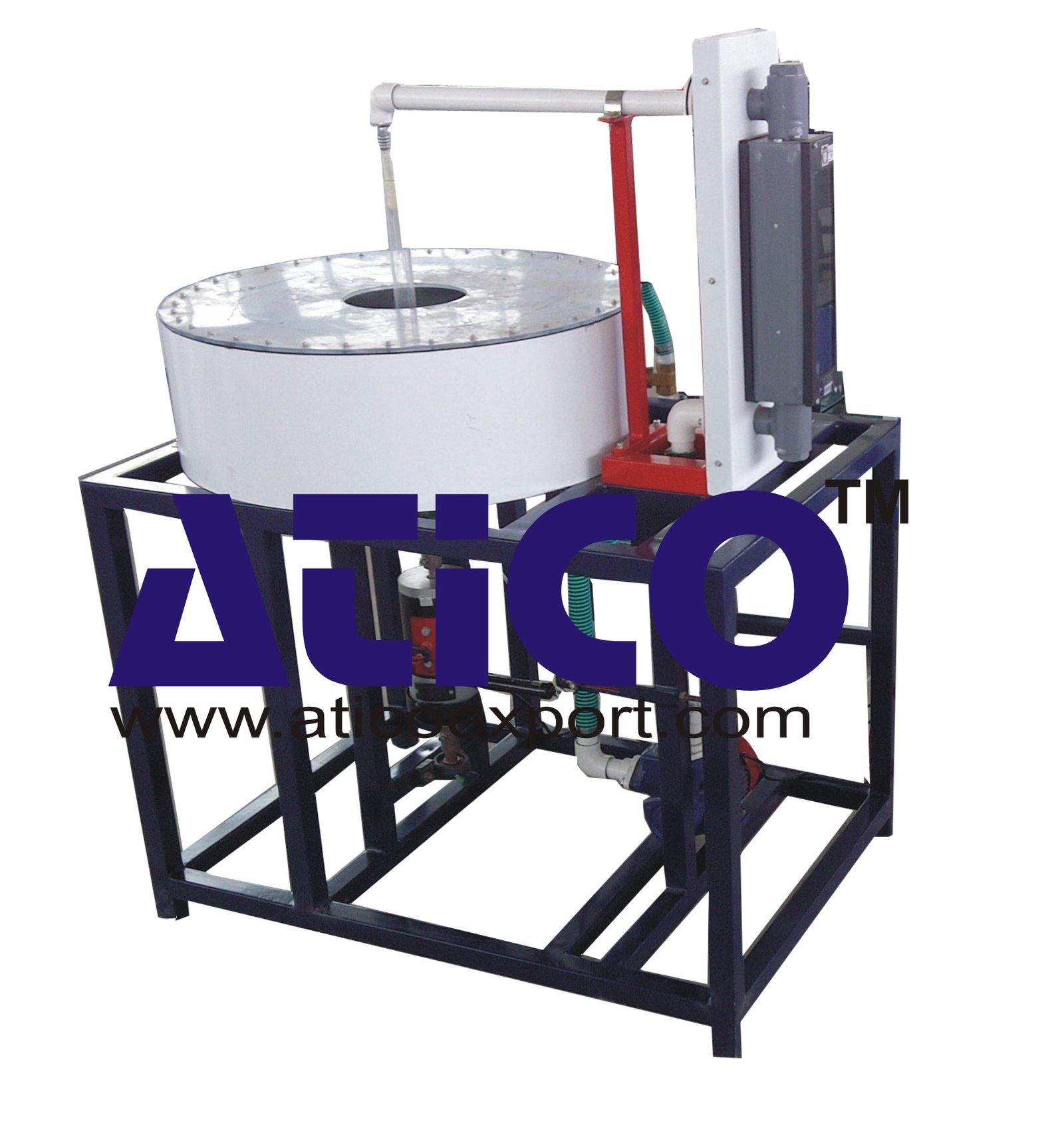

Rod Mills are horizontal rotating cylindrical steel chamber of half filled with steel rods of length slightly less than the length of chamber. The rods are of different diameter. The size reduction is accomplished by the impact of rods as they fall back after being lifted by the rotating chamber. Rod Mill is fitted on a sturdy MS frame. Charging of rods and material is done by the means of opening provided in the chamber. The chamber is turning about the horizontal axis through a reduction gearbox drive through a ½ HP motor. The stepped pulley arrangement is done for moving the Rod Mill at three different speeds. A revolution counter is provided to find out the number of turns. Special arrangement is done to free the Rod Mill from reduction gearbox for charging and discharging the material.

Experimentation:

- To study effect of RPM on the power consumption of a Rod Mill.

- To determine the efficiency of a Rod Mill for grinding a material of known

Utilities Required :

- Raw Material for Feed.

- Electric Supply : Single phase, 220 V AC, 1 kW.

- Set of Sieves with Sieve Shaker for analysis.

- Floor area 1.5 x 1m

Technical Details :

| Rod Mill | : Material MS |

| : Dia 275mm, Length 350mm. Thickness 5 mm | |

| Discharge Chute | : Suitable size. |

| Drive | : ½ HP motor coupled to Reduction Gearbox & 3 step pulley to get 40, 50 and 60 RPM (Approx.) |

| Revolution Counter | : Mechanical type. |

| Product receiver | : Material Stainless Steel of suitable size. |

| Control Panel Comprises of: | |

| Energy Measurement | : Electronic Energy meter. |

| MCB | : For overload protection. |

| : Standard make on/off switch, Mains Indicator etc. | |

| Instruction Manual | : An ENGLISH instruction manual will be provided along with the Apparatus |

| The set-up is fitted with required guards. | |

| The whole set-up is well designed and arranged in a good quality painted structure. | |

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.