Verification of Stress Hypotheses

Categories:Verification of Stress Hypotheses Technical Description: Stress hypotheses are applied in the science of the strength of materials when calculating comparative stresses where unequal stresses are com...

Product

Description

Verification of Stress Hypotheses

Technical Description:

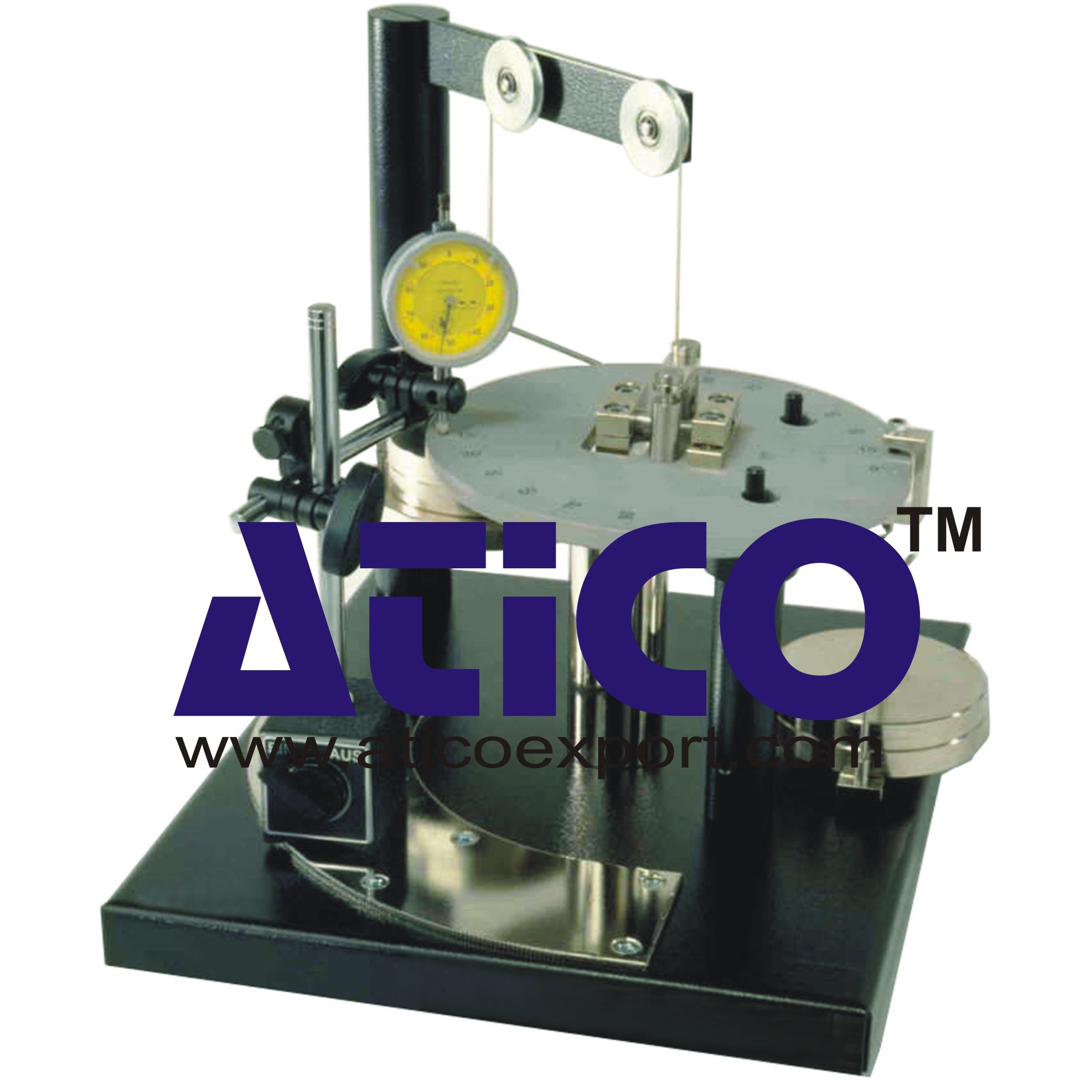

Stress hypotheses are applied in the science of the strength of materials when calculating comparative stresses where unequal stresses are combined. The following stress hypotheses, taking into account material properties, have been tried and proven in practice: Rankine yield criterion (direct stress hypothesis), von Mises yield criterion (change of shape hypothesis) and Tresca yield criterion (shear stress hypothesis). The experimental unit is used to verify these comparative stress hypotheses on test specimens made of various metals. For the purpose, a multi-axial stress state is produced at a point on the specimen and the resulting deformation is measured. The specimen is clamped on one end to the fixed frame. A loading plate is clamped to the specimen on the other end. A weight is attached on the outer circumference of the plate. A balance weight compensates for the dead-weight of the plate and the loading weight. As a result only direct and shearing stress occur at a point on the test specimen and shear forces are avoided. The loading plate has a graduation grid enabling weights to be attached at 15° increments. This permits purely bending moment and tor as well as combined load moments to be achieved. Diametrically opposite the weight load, measurement points are provided on the loading plate to measure the deformation. This enables the deformation at the point of maximum deflection to be measured. The various elements of the experiment are clearly laid-out and housed securely in a storage system. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specification:

1. Experiments verifying comparative stress hypotheses from the science of the strength of materials 2. 7 different load combinations of bending and torsion 3. Loading of the test specimen without shear force by compensation for the influence of dead-weight 4. Test specimens made of steel, copper, brass, aluminium 5. Generation of load moments by means of weight and lever arm 6. Measurement of the deformation at the point of maximum deflection 7. Storage system to house the components

Technical Data:

Specimens

- length: 49mm - clamping length: 11,5mm - specimen diameter in measurement cross-section: d=4mm

Set of weights to place load on specimens

- 1x 2N (hanger), 1x 1N, 1x 2N, 1x 4N, 2x 8N

Set of weights to compensate for the load and the loading plate

- 1x1N, 2x2N, 1x4N, 2x8N

Lever arm: 100mm

Deformation

- measuring range: 0...10mm - graduations: 0,01mm

quick overview :

Verification of Stress Hypotheses

Technical Description:

Stress hypotheses are applied in the science of the strength of materials when calculating comparative stresses where unequal stresses are combined. The following stress hypotheses, taking into account material properties, have been tried and proven in practice: Rankine yield criterion (direct stress hypothesis), von Mises yield criterion (change of shape hypothesis) and Tresca yield criterion (shear stress hypothesis). The experimental unit is used to verify these comparative stress hypotheses on test specimens made of various metals. For the purpose, a multi-axial stress state is produced at a point on the specimen and the resulting deformation is measured. The specimen is clamped on one end to the fixed frame. A loading plate is clamped to the specimen on the other end. A weight is attached on the outer circumference of the plate. A balance weight compensates for the dead-weight of the plate and the loading weight. As a result only direct and shearing stress occur at a point on the test specimen and shear forces are avoided. The loading plate has a graduation grid enabling weights to be attached at 15° increments. This permits purely bending moment and tor as well as combined load moments to be achieved. Diametrically opposite the weight load, measurement points are provided on the loading plate to measure the deformation. This enables the deformation at the point of maximum deflection to be measured. The various elements of the experiment are clearly laid-out and housed securely in a storage system. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Specification:

1. Experiments verifying comparative stress hypotheses from the science of the strength of materials 2. 7 different load combinations of bending and torsion 3. Loading of the test specimen without shear force by compensation for the influence of dead-weight 4. Test specimens made of steel, copper, brass, aluminium 5. Generation of load moments by means of weight and lever arm 6. Measurement of the deformation at the point of maximum deflection 7. Storage system to house the components

Technical Data:

Specimens

- length: 49mm - clamping length: 11,5mm - specimen diameter in measurement cross-section: d=4mm

Set of weights to place load on specimens

- 1x 2N (hanger), 1x 1N, 1x 2N, 1x 4N, 2x 8N

Set of weights to compensate for the load and the loading plate

- 1x1N, 2x2N, 1x4N, 2x8N

Lever arm: 100mm

Deformation

- measuring range: 0...10mm - graduations: 0,01mm

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.