Water Temperature Control Bench Hydrotherm

Categories:Water Temperature Control Bench Hydrotherm Teaching Objectives of Water Temperature Control Bench Hydrotherm The bench is designed to be self-contained and only need an electrical power supply. It a...

Product

Description

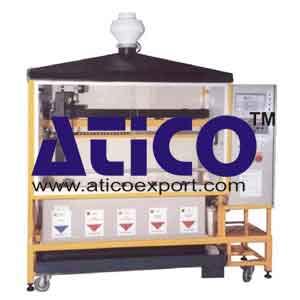

Water Temperature Control Bench Hydrotherm

Teaching Objectives of Water Temperature Control Bench Hydrotherm The bench is designed to be self-contained and only need an electrical power supply. It allows to study an important number of subjects: Temperature Sensor- Sensor performance (answer time, linearity, hysteresis).

- Justification about to use a continuous current power generator.

- Justification of the wiring with 3 wires.

- Functioning principle of the modulators.

- Problem of peak intensity during the starting.

- Modulators performance: Static power unit, Wave train dimmer.

- Functioning cycle, life time

- Calculation of the heating power.

- Observation of the temperature influence when bringing a cold piece.

- Experimental determination of the heat loss coefficient.

- Temperature distribution in the bench.

- Influence of the water level

- Temperature Control.

- Automatic control methods.

- Adjustment by discontinuous actions.

- Controller P.

- Controller PI.

- Controller PID.

- Controller PID self adaptative.

- Process answer.

- Temporal analysis.

- Influence of the setting, the mass of water, the disturbance.

Technical specifications

Operative Part: The bench is made out of an aluminium frame on castors including:- A 25 litres tank.

- An immersed electrical heater.

- A temperature sensor.

- A " low level" sensor.

- A security thermostat.

- A stainless steel body centrifugal circulation pump.

The data acquisition system is proposed in option. It is made out of a data acquisition card to place into a PC computer and a software functioning under Windows®. This software allow to visualize the sizes in real time and to record them. The card is linked to the bench by the help of a plug on the front side of the electrical cabinet door.

Control Part: An electric cabinet including:- The power supply and safety devices of the installation: circuit breaker, contactor, fuses, transformer.

- The heating controller: 1 power unit by train of waves.

- A dimmer (in option) can be connected on the side of the cabinet (the use of another dimmer that the one proposed in option is possible on special enquiry).

- A converter for the Pt 100 probe.

- The control components.

- A PID controller auto adaptive.

- A thermostat.

- The controller and the thermostat are integrated in a synoptic on the front side of the cabinet. The synoptic, also include various measuring points permitting the study of the control loop.

- 1150 x 670 x 1470 mm - 98 kg

- Electrical power supply: single phase 230 V+T 16A

quick overview :

Water Temperature Control Bench Hydrotherm

Teaching Objectives of Water Temperature Control Bench Hydrotherm The bench is designed to be self-contained and only need an electrical power supply. It allows to study an important number of subjects: Temperature Sensor- Sensor performance (answer time, linearity, hysteresis).

- Justification about to use a continuous current power generator.

- Justification of the wiring with 3 wires.

- Functioning principle of the modulators.

- Problem of peak intensity during the starting.

- Modulators performance: Static power unit, Wave train dimmer.

- Functioning cycle, life time

- Calculation of the heating power.

- Observation of the temperature influence when bringing a cold piece.

- Experimental determination of the heat loss coefficient.

- Temperature distribution in the bench.

- Influence of the water level

- Temperature Control.

- Automatic control methods.

- Adjustment by discontinuous actions.

- Controller P.

- Controller PI.

- Controller PID.

- Controller PID self adaptative.

- Process answer.

- Temporal analysis.

- Influence of the setting, the mass of water, the disturbance.

Technical specifications

Operative Part: The bench is made out of an aluminium frame on castors including:- A 25 litres tank.

- An immersed electrical heater.

- A temperature sensor.

- A " low level" sensor.

- A security thermostat.

- A stainless steel body centrifugal circulation pump.

The data acquisition system is proposed in option. It is made out of a data acquisition card to place into a PC computer and a software functioning under Windows®. This software allow to visualize the sizes in real time and to record them. The card is linked to the bench by the help of a plug on the front side of the electrical cabinet door.

Control Part: An electric cabinet including:- The power supply and safety devices of the installation: circuit breaker, contactor, fuses, transformer.

- The heating controller: 1 power unit by train of waves.

- A dimmer (in option) can be connected on the side of the cabinet (the use of another dimmer that the one proposed in option is possible on special enquiry).

- A converter for the Pt 100 probe.

- The control components.

- A PID controller auto adaptive.

- A thermostat.

- The controller and the thermostat are integrated in a synoptic on the front side of the cabinet. The synoptic, also include various measuring points permitting the study of the control loop.

- 1150 x 670 x 1470 mm - 98 kg

- Electrical power supply: single phase 230 V+T 16A

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.